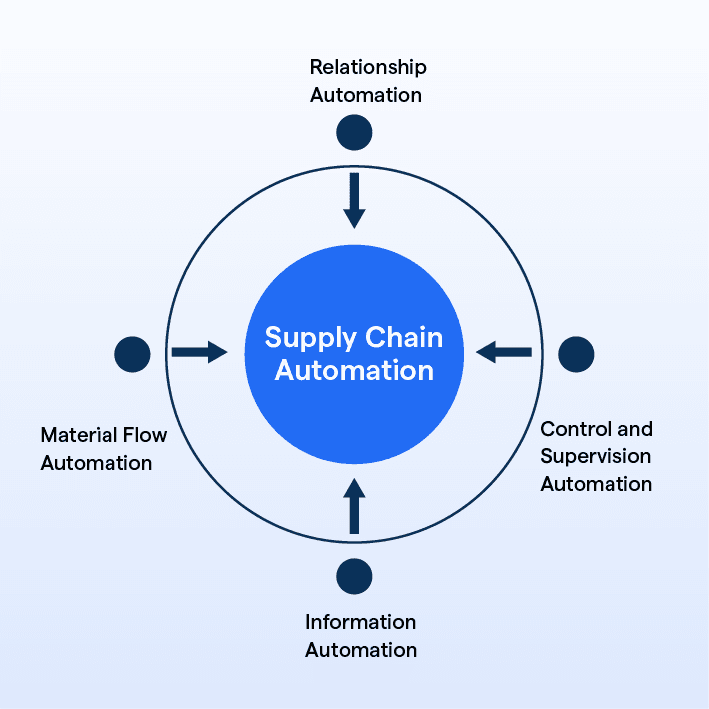

Artificial intelligence in supply chain management refers to the use of machine learning, predictive analytics, and automation technologies to optimize the flow of goods, information, and resources across business networks.

Supply chains have become increasingly complex as companies operate across global markets with multiple suppliers, distributors, and customers. Traditional supply chain management relies heavily on manual processes and historical data, which can lead to inefficiencies and missed opportunities. Modern supply chains face constant pressure from changing customer demands, geopolitical disruptions, and environmental concerns.

Source: Supply Chain Movement

AI technologies offer solutions to these challenges by processing vast amounts of data in real-time and identifying patterns that humans might miss. These systems can predict future demand, optimize transportation routes, and automate routine tasks. The technology enables supply chain managers to make faster, more informed decisions based on comprehensive data analysis.

Companies implementing AI in their supply chains report significant improvements in cost reduction, operational efficiency, and customer satisfaction. These results demonstrate the tangible benefits that AI can deliver when properly implemented across supply chain operations.

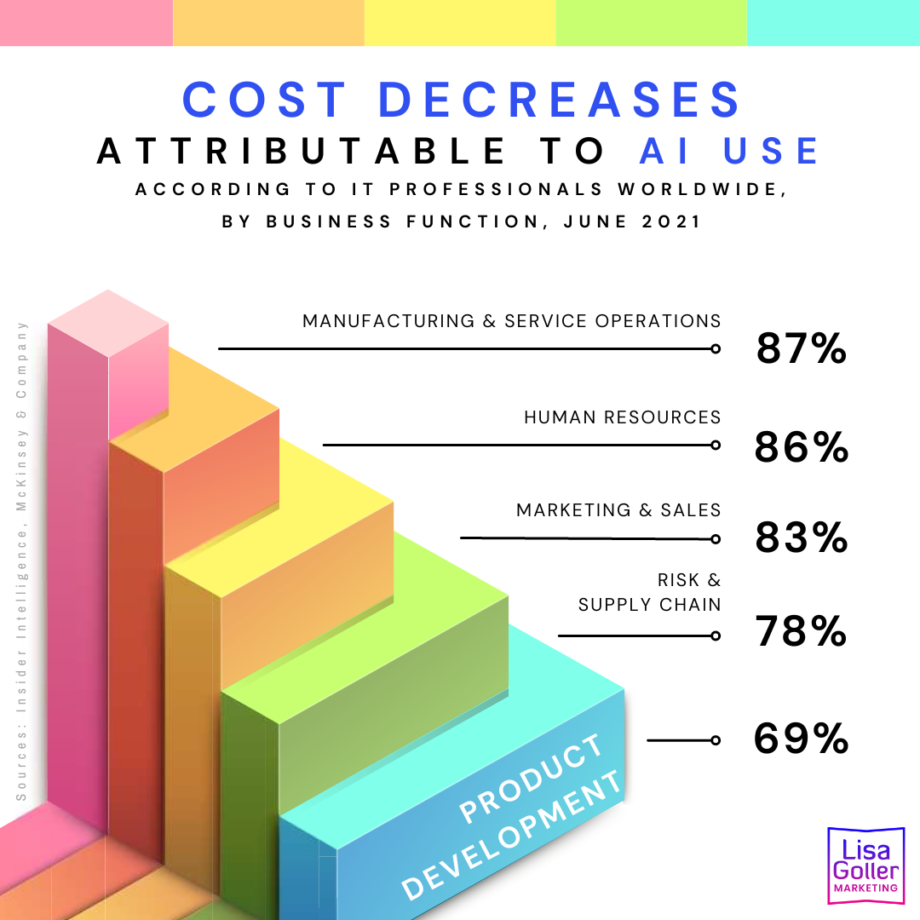

How AI Reduces Supply Chain Costs

AI technologies deliver measurable cost reductions across supply chain operations through automation, optimization, and waste elimination. Companies implementing comprehensive AI solutions report savings ranging from millions to hundreds of millions of dollars annually.

Source: Lisa Goller Marketing

These cost reductions occur through automation of routine tasks that previously required manual labor, optimization algorithms that identify the most efficient routes and resource allocation strategies, and predictive capabilities that prevent waste by anticipating demand more accurately.

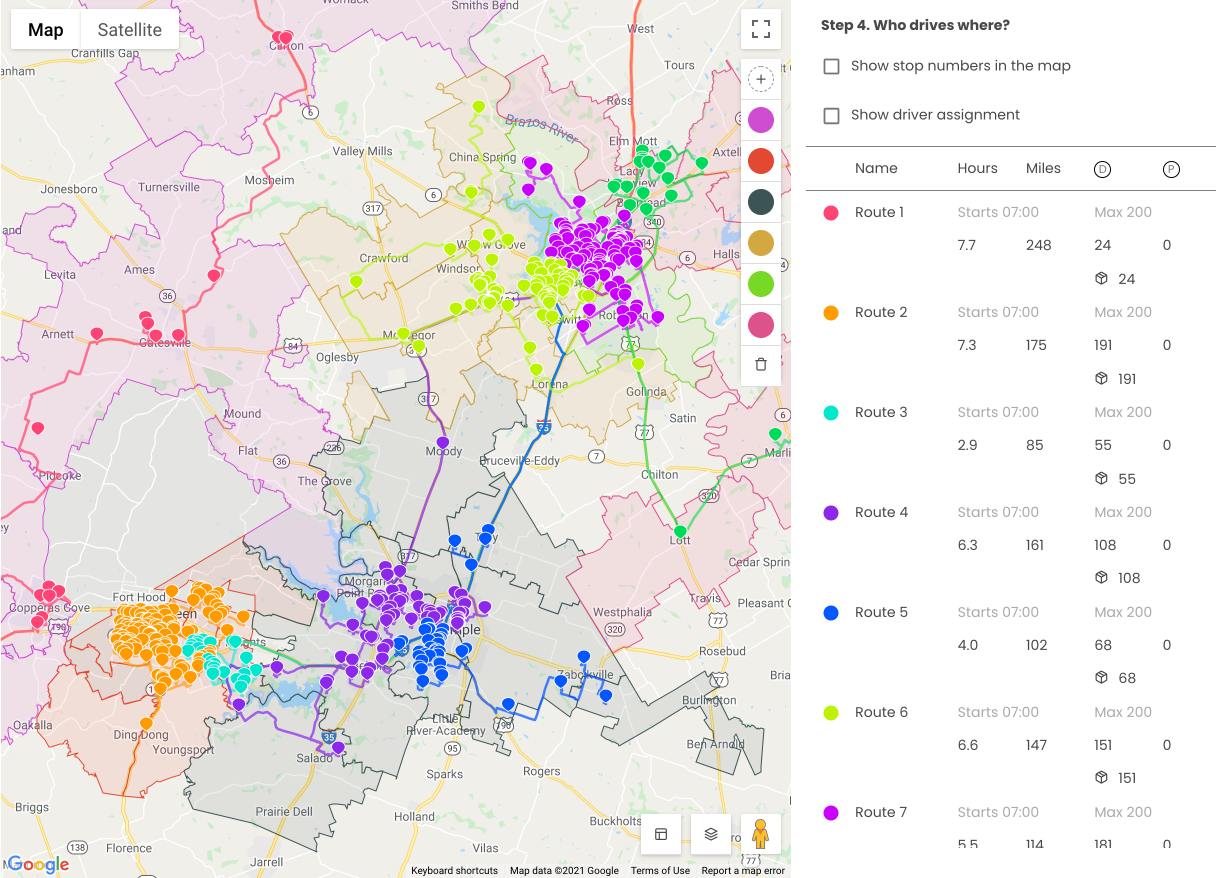

Transportation and Logistics Cost Savings

AI-powered transportation systems analyze real-time traffic conditions, weather patterns, delivery requirements, and vehicle capacities to identify optimal routing strategies. Route optimization algorithms process vast amounts of data to determine the most fuel-efficient paths while maintaining delivery schedules.

Source: Beans.ai

Transportation cost savings include:

- Fuel consumption reduction — Optimized routes reduce total miles driven and avoid traffic congestion

- Vehicle utilization improvement — AI coordinates loads to maximize cargo capacity per trip

- Carrier selection optimization — Algorithms evaluate cost, performance, and reliability data to choose the best shipping partners

- Delivery time reduction — Faster routes decrease labor costs and improve customer satisfaction

These systems can reduce documentation lead times by up to 60 percent while minimizing human errors in shipping paperwork. One last-mile delivery operator reported significant savings from a smaller initial investment in AI technology.

Inventory Management Improvements

Inventory carrying costs represent the expenses associated with storing unsold goods, including warehouse space, insurance, taxes, obsolescence, and opportunity costs of tied-up capital. These costs typically range from 20 to 30 percent of inventory value annually.

Source: LinkedIn

AI prevents overstocking by analyzing demand patterns, seasonal variations, and external factors to predict future inventory needs more accurately. Traditional inventory management often results in either excess inventory that ties up working capital or insufficient inventory that leads to stockouts and lost sales.

Machine learning algorithms optimize warehouse layouts by evaluating material flow patterns and suggesting floor plans that minimize travel times. AI systems coordinate inventory movement from receiving to storage to shipping stations, reducing handling costs and improving fulfillment speed.

Labor Cost Optimization Through Automation

AI systems automate routine tasks across supply chain operations, enabling organizations to reallocate human workers to higher-value strategic activities. Research indicates that 43 percent of all working hours across end-to-end supply chain activities could be impacted by AI, with 29 percent potentially automated and 14 percent significantly augmented.

Source: BotPenguin

Automated processes include document generation, data entry and processing, inventory tracking, quality control inspection, order processing, supplier communication, and scheduling optimization. Warehouse operations benefit from AI coordination between human workers, robotic systems, and automated equipment.

Virtual dispatcher agents assist drivers with troubleshooting and roadside assistance, reducing support costs and improving delivery reliability. This aligns with how AI agents in customer service improve operational efficiency. AI-powered maintenance systems monitor equipment performance and predict potential failures, automatically scheduling maintenance to minimize downtime.

Operational Efficiency Gains Through AI Implementation

AI transforms supply chain operations by automating manual processes and providing instant visibility into performance metrics. These systems process vast amounts of operational data in real-time, enabling continuous optimization across inventory management, production scheduling, transportation routing, and warehouse operations.

Organizations implementing comprehensive AI solutions report dramatic improvements in operational efficiency. The technology enables supply chain managers to compress decision cycles from days to hours or even minutes through instant access to comprehensive operational intelligence.

Process Automation and Workflow Optimization

AI systems excel at handling repetitive tasks that previously required manual intervention. Machine learning algorithms identify patterns in operational data and execute standardized processes with greater speed and accuracy than human operators.

Automated document generation reduces lead times for shipping documentation by up to 60 percent while minimizing human errors. AI systems coordinate warehouse activities, plan optimal routes for inventory movement, and dynamically adjust operations based on changing demand patterns and resource availability.

Key automated processes include order processing with automated purchase order generation and supplier communication, quality control through automated visual inspections and defect detection, and transportation planning with automated route optimization and shipment scheduling.

Real-Time Performance Monitoring

Real-time monitoring refers to the continuous tracking and analysis of operational metrics as events occur, providing immediate insights into performance status without delays. Traditional monitoring systems typically update hourly or daily, while real-time systems process data within seconds or minutes of generation.

Source: Budibase

AI-powered monitoring systems analyze sensor data from equipment, track inventory movements, monitor transportation progress, and evaluate quality metrics continuously. These systems detect anomalies, identify bottlenecks, and alert operators to potential issues before they escalate into major problems.

Performance dashboards display live metrics including production rates, delivery status, equipment utilization, and quality scores. Machine learning algorithms establish baseline performance patterns and automatically flag deviations that may indicate operational issues or optimization opportunities.

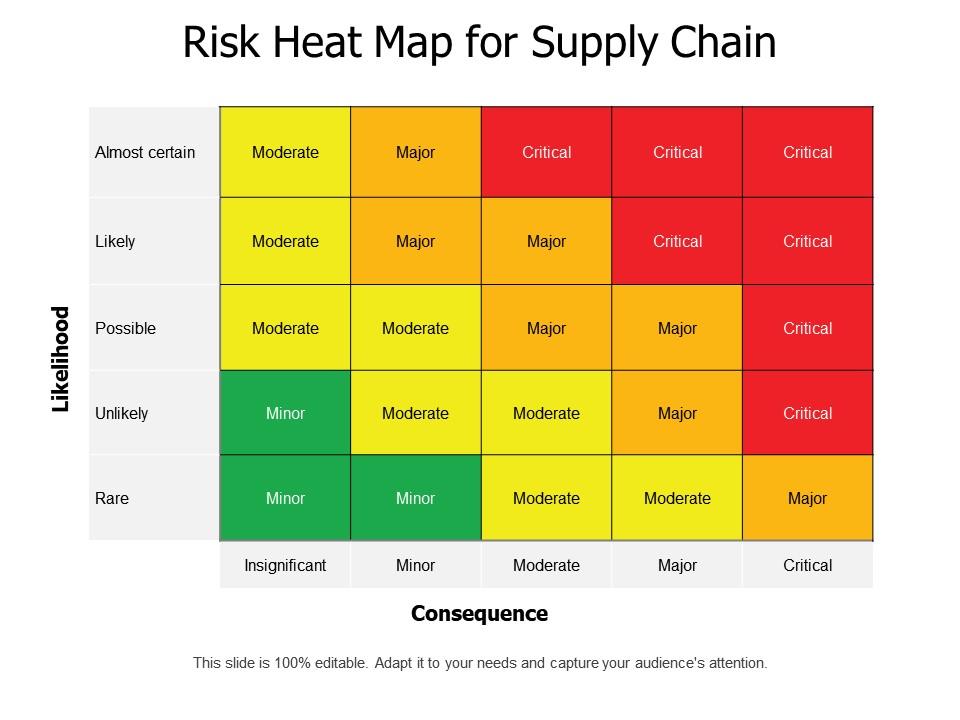

Enhanced Risk Management and Supply Chain Resilience

AI transforms how organizations protect their supply chains from unexpected problems. Modern supply chains face constant threats from weather events, economic changes, and supplier failures that can disrupt operations within hours.

Source: SlideTeam

AI systems analyze massive amounts of data to spot patterns that indicate trouble ahead, giving companies time to prepare before disruptions occur. Traditional risk management relies on humans reviewing reports after problems happen, while AI changes this approach by continuously monitoring thousands of data sources simultaneously.

Predictive Risk Assessment and Early Warning Systems

AI systems identify potential supply chain problems by analyzing patterns in data from multiple sources. These systems process information faster than human teams and detect relationships between seemingly unrelated events that signal incoming disruptions.

Risk identification happens through continuous monitoring of weather disruptions, supplier issues, transportation problems, geopolitical events, and economic fluctuations. AI tracks meteorological data and historical weather patterns to predict storms and extreme temperature events that affect transportation routes and manufacturing facilities.

Early warning systems generate alerts when risk levels exceed predetermined thresholds. Organizations receive advance notice ranging from hours to months depending on the type of threat. This advance warning creates opportunities to implement protective measures before disruptions impact operations.

Disruption Response and Contingency Planning

Supply chain resilience describes an organization’s ability to maintain operations during disruptions and recover quickly afterward. AI enhances resilience by automating response procedures and activating backup plans when problems occur.

Rapid response strategies rely on AI systems that can execute predetermined actions without waiting for human approval. When early warning systems detect incoming threats, AI platforms automatically trigger contingency procedures, including rerouting shipments through alternative transportation networks and activating backup suppliers.

Response coordination involves AI platforms communicating with multiple suppliers and logistics providers simultaneously. The technology negotiates alternative arrangements, updates delivery schedules, and adjusts production plans across the entire network.

Improved Decision Making with AI-Powered Analytics

AI transforms how business leaders make decisions by processing vast amounts of information and presenting clear insights in seconds rather than days. Traditional decision-making often relies on outdated reports and gut instincts, while AI-powered analytics provides real-time data analysis that reveals patterns humans might miss.

AI systems analyze multiple data sources simultaneously, including sales figures, customer behavior, market trends, and external factors like weather or economic indicators. The technology identifies relationships between different variables and presents findings in easy-to-understand dashboards and reports.

Predictive Analytics for Strategic Planning

Predictive analytics uses historical data and statistical algorithms to forecast future events and trends. The technology examines patterns from past performance to predict what might happen next, helping organizations plan for various scenarios and allocate resources effectively.

Source: ResearchGate

Machine learning algorithms analyze years of historical data to identify recurring patterns and seasonal trends. The systems consider multiple variables simultaneously, such as economic conditions, consumer behavior changes, and industry developments.

Strategic planning benefits from scenario modeling that tests different future possibilities. Organizations can explore questions about competitor actions or supply chain disruptions. These capabilities align with generative AI vs predictive AI approaches to provide data-driven answers to guide strategic decisions rather than relying on assumptions.

Real-Time Data Processing and Insights

Real-time data processing means analyzing information as it arrives rather than waiting for scheduled reports. AI systems continuously monitor data streams and alert decision-makers when significant changes occur or when immediate action becomes necessary.

Modern AI platforms can analyze sales transactions, inventory levels, social media mentions, market prices, weather conditions, equipment performance, and financial markets simultaneously. The immediate analysis capability enables organizations to respond quickly to changing conditions.

Dashboard interfaces display real-time information in visual formats that make patterns and trends easy to understand. Charts, graphs, and color-coded alerts help decision-makers quickly grasp complex situations without analyzing detailed reports.

Advanced Inventory Management and Demand Forecasting

AI transforms how companies predict what customers will buy and manage their stock levels. Traditional inventory management relied on historical sales data and basic calculations, often resulting in too much inventory sitting in warehouses or empty shelves when customers wanted to purchase items.

AI systems process vast amounts of information from multiple sources to create accurate predictions and automatically adjust inventory levels in real-time. These systems learn from their own prediction accuracy over time, continuously improving forecasts as they process more data.

AI-Driven Demand Prediction Accuracy

Demand forecasting predicts how much of each product customers will want to buy during specific time periods. AI systems analyze dozens of data sources simultaneously to create these predictions, including past sales records, current market conditions, weather patterns, economic indicators, social media trends, and competitor activities.

Source: ResearchGate

Machine learning algorithms identify patterns humans might miss when examining sales data. These systems recognize correlations between seemingly unrelated factors, such as how rainy weather increases umbrella sales but also affects grocery shopping patterns.

AI demand forecasting systems learn from their own prediction accuracy over time. When actual sales differ from predictions, the algorithms automatically adjust their models to improve future forecasts. This continuous learning process means prediction accuracy improves as the system experiences different market conditions.

Dynamic Inventory Optimization

Dynamic inventory optimization uses AI to automatically adjust stock levels based on real-time demand signals and supply chain conditions. These systems calculate optimal inventory quantities for each product location, considering factors like storage costs, delivery times, and the financial impact of stockouts versus excess inventory.

AI optimization considers sales velocity for fast-moving items that require frequent replenishment versus slow-moving items that need careful monitoring to prevent obsolescence. Seasonality creates predictable demand patterns that require inventory buildup weeks or months in advance.

AI systems automatically generate purchase orders when inventory reaches calculated reorder points. These systems factor in supplier lead times, minimum order quantities, bulk pricing discounts, and transportation schedules to optimize both inventory levels and procurement costs.

Superior Customer Experience and Service Delivery

AI transforms customer experience in supply chains by reducing delivery times and minimizing errors throughout the order process. When companies implement AI systems, customers receive orders faster and with greater accuracy than traditional manual processing methods allow.

Source: Solistica

The technology analyzes customer data, inventory levels, and logistics networks simultaneously to optimize every step of the fulfillment process. Customers experience consistent service levels even during peak demand periods or supply chain disruptions.

Faster Order Fulfillment and Delivery

AI accelerates order processing by automating inventory allocation, routing decisions, and shipment scheduling. Machine learning algorithms analyze historical patterns and current conditions to identify the fastest fulfillment path for each order.

The order fulfillment cycle encompasses every step from initial order placement through final delivery to the customer. AI systems compress fulfillment timeframes by optimizing warehouse operations and transportation routes.

Processing automation eliminates manual data entry delays and reduces human errors that can slow order progression. AI validates order information, checks inventory availability, and generates shipping documentation in seconds rather than minutes or hours.

Proactive Customer Communication

AI-powered communication systems provide automatic updates throughout the order journey without requiring manual intervention. These systems monitor order status in real-time and trigger notifications when specific milestones occur.

Customer communication includes order confirmation messages, inventory allocation notifications, shipping confirmations with tracking information, in-transit updates, delivery scheduling notifications, and exception alerts for delays. Smart notification systems personalize communication timing and methods based on individual customer preferences.

AI analyzes delivery data to provide accurate time estimates that account for local conditions and carrier performance patterns. This capability connects to how AI agents in sales enhance customer interactions. Customers receive realistic delivery windows rather than generic timeframes that often prove inaccurate.

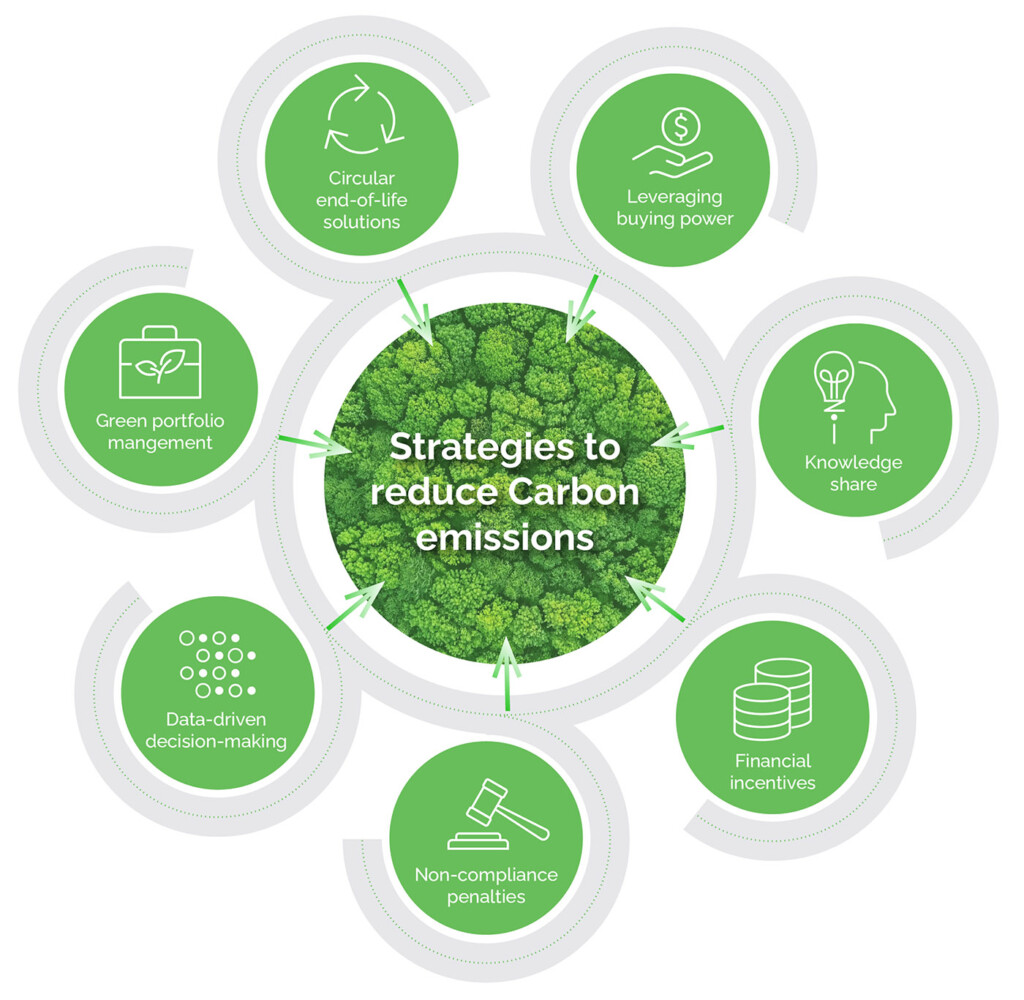

Sustainability Benefits and Environmental Impact Reduction

AI enables organizations to track, measure, and optimize their environmental impact across entire supply chain networks while identifying opportunities for resource conservation and waste reduction. Organizations implementing AI technologies report achieving significant reductions in environmental impact through optimized transportation routes, reduced energy usage, and improved resource efficiency.

Source: Everstream Analytics

AI systems analyze environmental impact data across multiple dimensions including carbon emissions, resource consumption, waste generation, and energy utilization to identify optimization opportunities that simultaneously improve sustainability performance and operational efficiency.

Carbon Footprint Optimization

AI-powered route optimization systems analyze real-time traffic conditions, weather patterns, delivery requirements, and vehicle capacities to identify the most efficient routing strategies. Carbon footprint in supply chain context refers to the total greenhouse gas emissions produced throughout the movement of goods from suppliers to customers.

AI systems can reduce fuel consumption, minimize delivery times, and improve asset utilization rates through intelligent routing algorithms. AI-driven analytics optimize energy consumption in manufacturing and warehouse operations by monitoring equipment performance and adjusting operations based on energy efficiency metrics.

These optimization efforts help organizations meet environmental compliance requirements while reducing operational costs through improved efficiency and resource utilization.

Waste Reduction Through Better Planning

AI-powered demand forecasting systems analyze historical patterns, market trends, seasonal variations, and external factors to provide accurate predictions of future demand, reducing overproduction and excess inventory. Improved forecasting accuracy enables organizations to optimize inventory levels and minimize obsolescence while maintaining high service levels.

AI systems identify specific waste reduction opportunities including food waste by tracking expiration dates and predicting spoilage patterns, packaging waste through optimal package size calculations, and material waste through improved production planning and quality control processes.

Frequently Asked Questions About AI Supply Chain Benefits

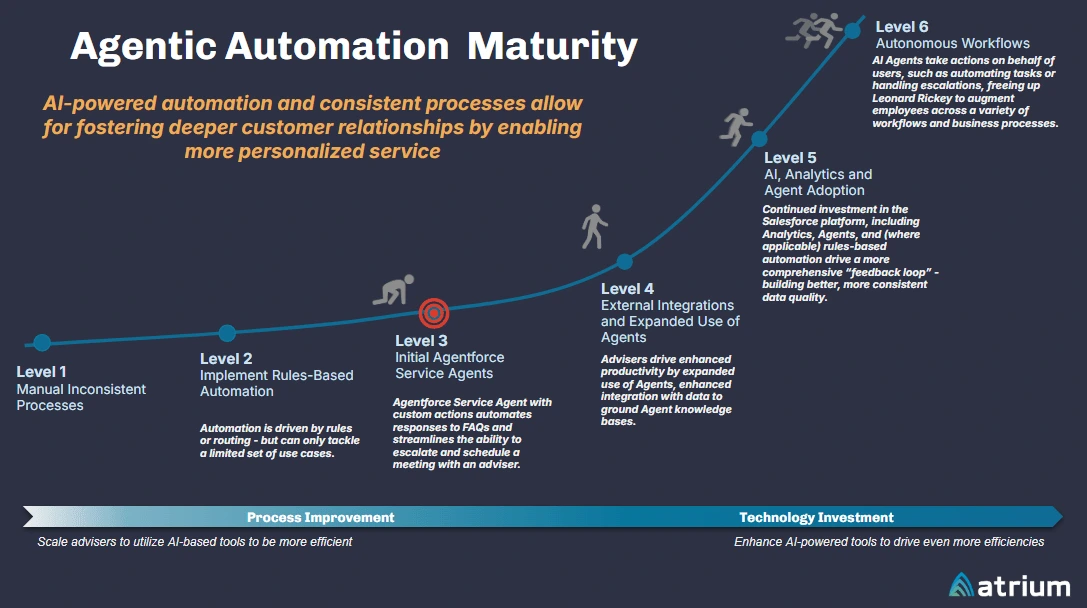

Source: Atrium’s AI

What cost savings can companies expect from implementing AI in their supply chains?

Companies typically see cost reductions ranging from millions to hundreds of millions of dollars annually depending on implementation scope and company size. Transportation optimization alone can reduce fuel consumption by 15 to 20 percent through improved routing and load coordination.

Inventory carrying cost reductions occur through better demand forecasting that prevents overstocking and stockouts. Labor cost optimization happens through automation of routine tasks, with research showing 29 percent of supply chain working hours could potentially be automated.

How long does it take to see results from AI supply chain implementation?

Most organizations see initial improvements within three to six months of implementing focused AI applications like demand forecasting or route optimization. Full benefits typically emerge within 12 to 18 months as systems learn from operational data and teams become proficient with new tools.

The timeline varies based on implementation approach, data quality, and organizational readiness. Companies starting with pilot projects in specific areas often see faster initial results than those attempting comprehensive transformations across all supply chain functions simultaneously. Understanding responsible AI principles can help ensure successful implementation.

Which supply chain processes benefit most from AI implementation?

Demand forecasting and inventory management typically deliver the highest initial returns because AI significantly improves prediction accuracy compared to traditional methods. Transportation and logistics optimization follows closely, offering immediate cost savings through route optimization and load planning improvements.

Warehouse operations automation provides efficiency gains through optimized layouts and coordinated movement planning. Risk management and supplier monitoring become increasingly valuable as organizations build predictive capabilities to identify potential disruptions before they impact operations.

What data requirements exist for successful AI supply chain implementation?

AI systems require clean, consistent data from multiple sources including historical sales records, inventory levels, supplier performance metrics, transportation costs, and operational data. The data must cover sufficient time periods to identify patterns, typically requiring at least two years of historical information.

External data sources enhance AI capabilities, including weather information, economic indicators, market trends, and social media sentiment data. Data quality matters more than quantity — accurate, well-structured information from fewer sources outperforms large volumes of inconsistent or incomplete data.

AI systems can help improve data quality during implementation by identifying inconsistencies and providing tools for cleaning and standardizing information across different business systems and partner networks. Organizations should consider AI consulting services to ensure proper implementation and data management strategies.