AI for operations management uses machine learning and predictive analytics to automate routine tasks, optimize processes, and improve decision-making for increased efficiency and reduced costs.

Modern organizations generate massive amounts of operational data every day. Traditional management approaches struggle to process this information quickly enough for optimal decision-making. AI technologies fill this gap by analyzing patterns, predicting outcomes, and automating responses faster than human teams.

Source: Appian

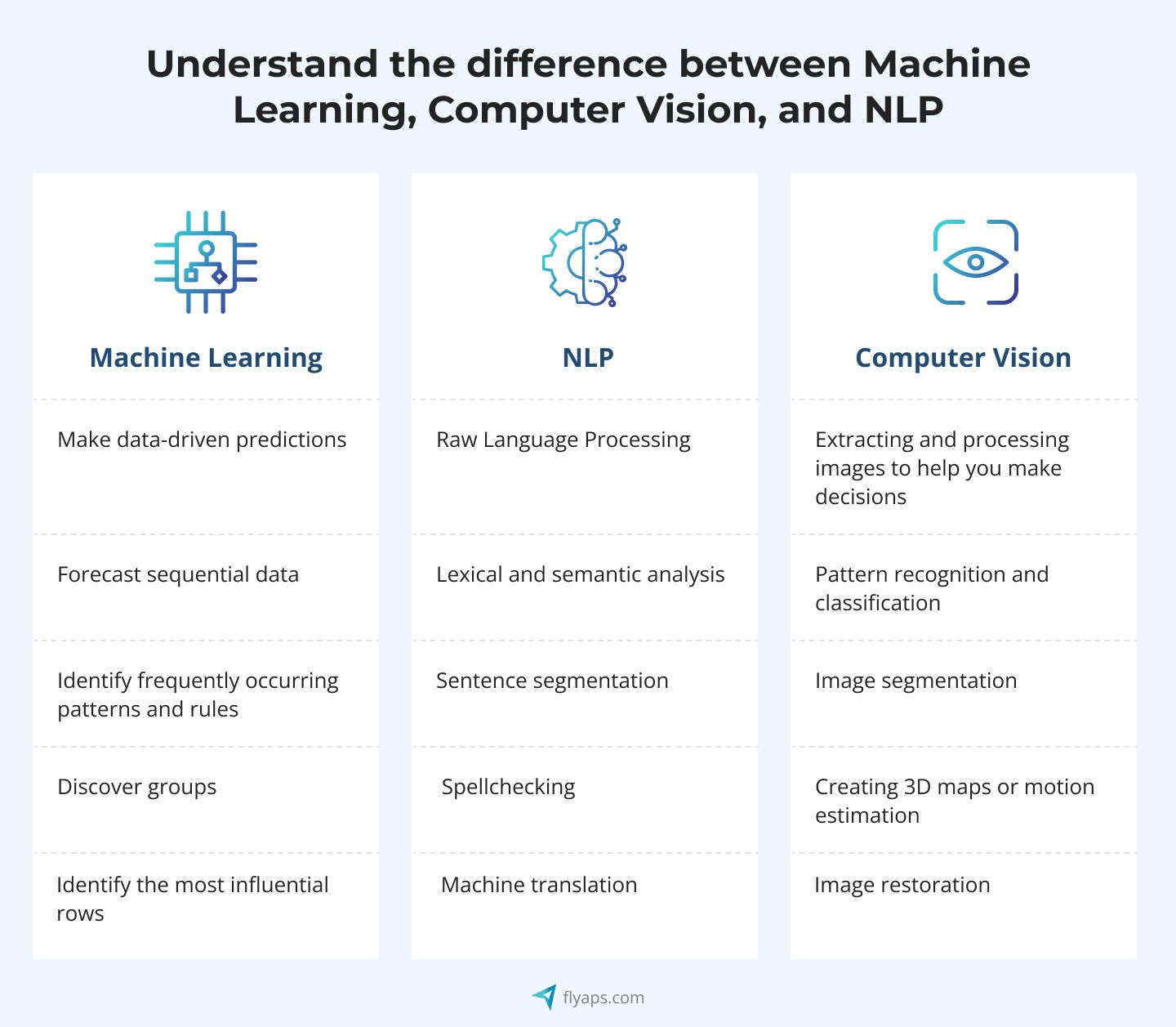

Machine learning algorithms learn from historical data to identify trends and make predictions. Predictive analytics forecast future events like equipment failures or demand changes. Automation executes routine tasks without human intervention, freeing staff for strategic work.

What AI Technologies Work in Operations Management

Machine learning forms the foundation of AI operations systems. These algorithms analyze historical performance data to identify patterns that predict future outcomes. Supervised learning uses labeled examples to train models, while unsupervised learning discovers hidden patterns in data without predetermined categories.

Source: Flyaps

Predictive analytics applies statistical models and machine learning to forecast operational events. Manufacturing companies use predictive analytics to anticipate equipment breakdowns before they occur. Supply chain teams forecast demand to optimize inventory levels and reduce stockouts.

Natural language processing enables AI systems to understand and generate human language. Operations teams use these tools to analyze customer feedback, process maintenance reports, and generate automated documentation. Computer vision analyzes images and video feeds for quality control and safety monitoring.

Robotic process automation handles repetitive digital tasks like data entry, invoice processing, and report generation. Unlike physical robots, RPA operates within existing software systems to complete routine workflows automatically without replacing entire systems.

Primary Applications of AI in Operations

Predictive Maintenance Systems

Predictive maintenance represents one of the most successful AI applications in operations. Sensors monitor equipment conditions like vibration, temperature, and pressure. Machine learning models analyze this data to predict failures weeks or months in advance.

Source: Worktrek CMMS

Companies implementing predictive maintenance see measurable improvements. According to the U.S. Department of Energy, predictive maintenance can reduce maintenance costs by 10 to 40 percent and eliminate breakdowns by 70 to 75 percent. Mining companies report 30 percent reductions in production downtime using AI-powered predictive maintenance systems.

The technology works by collecting continuous data from equipment sensors. Algorithms learn normal operating patterns and identify deviations that indicate potential problems. Maintenance teams receive alerts with specific recommendations about which components need attention and when to schedule repairs.

Supply Chain Optimization

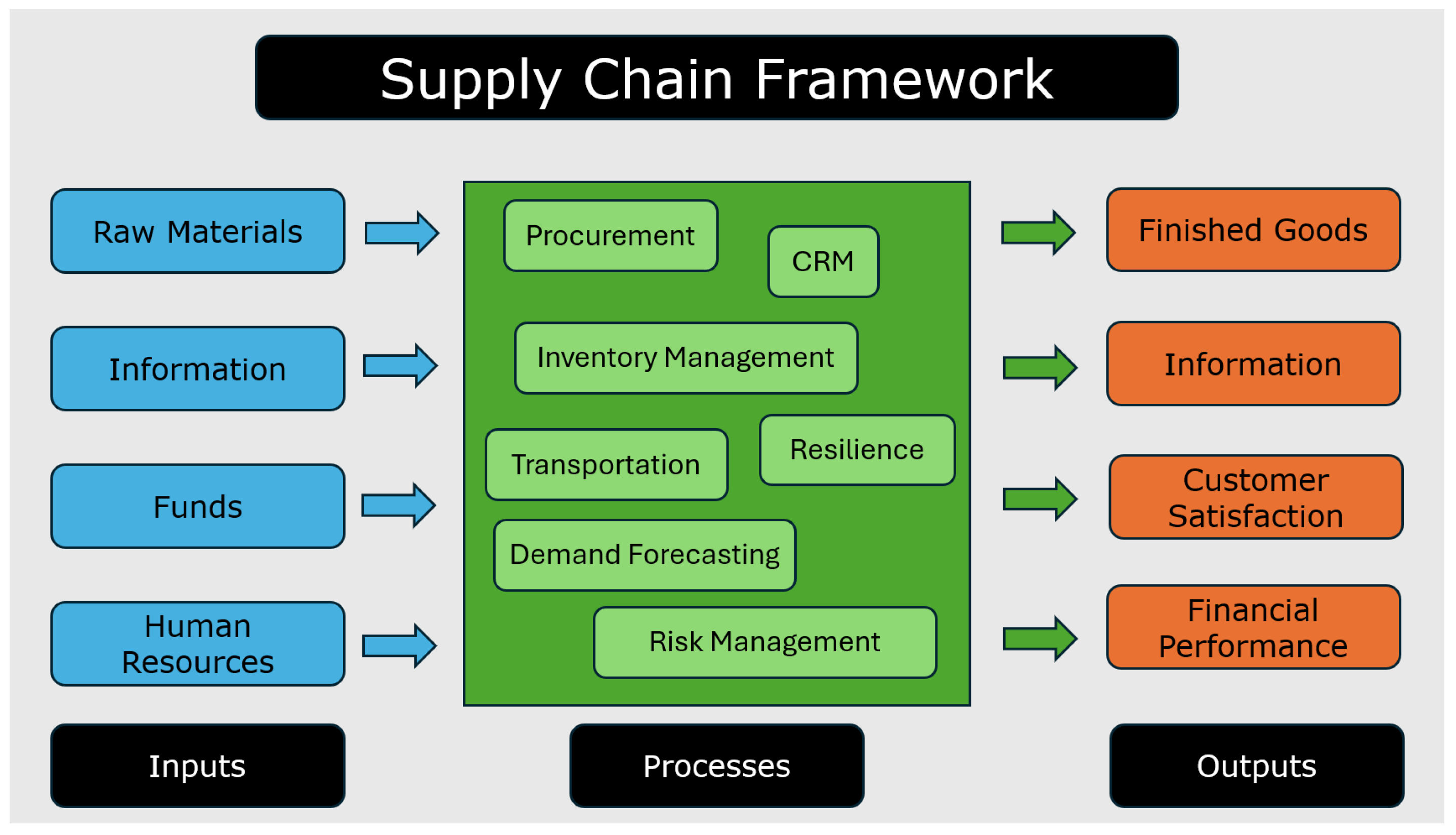

AI transforms supply chain management through improved demand forecasting and inventory optimization. Traditional forecasting methods rely on historical averages and seasonal adjustments. AI systems analyze multiple data sources including sales history, market trends, weather patterns, and social media sentiment.

Source: MDPI

Research from IBM shows AI-powered demand forecasting can reduce forecasting errors by up to 50 percent compared to traditional methods. This accuracy improvement directly translates to better inventory management and reduced stockouts or overstock situations.

Route optimization represents another key application. AI systems process real-time traffic data, weather conditions, and delivery constraints to optimize shipping routes. Companies report 15 to 20 percent reductions in transportation costs through AI-powered route optimization.

Quality Control Automation

Computer vision systems inspect products on production lines using cameras and image recognition algorithms. These systems detect defects that human inspectors might miss while operating continuously without fatigue or inconsistency.

Source: XenonStack

Manufacturing plants use AI for various quality control tasks:

- Surface defect detection on automotive parts

- Dimensional accuracy verification in electronics manufacturing

- Color consistency monitoring in textile production

- Assembly error identification in complex products

The technology learns to distinguish between acceptable products and those with defects by training on thousands of product images. Integration with production line controls enables automatic removal of defective items or alerts to operators.

Process Automation Enhancement

Intelligent automation combines RPA with AI capabilities to handle complex processes requiring interpretation and decision-making. Unlike simple rule-based automation, AI-enhanced systems adapt to variations in input formats and business rules.

Common automation applications include:

- Invoice processing that extracts data from any format

- Expense report routing that follows complex approval hierarchies

- Inventory updates that reconcile data across multiple systems

- Customer inquiry responses through intelligent chatbots

Organizations report significant time savings from intelligent automation. One financial services company reduced expense report processing from three hours to 10 minutes using AI-enhanced automation.

Benefits of AI Implementation

Cost Reduction Through Optimization

AI optimizes resource utilization by analyzing operational data to identify waste and inefficiencies. Equipment monitoring systems predict optimal maintenance schedules, reducing both planned and unplanned downtime. Energy management systems adjust consumption based on real-time demand and pricing.

Source: Neurons Lab

Preventing costly equipment failures represents a major source of savings. The National Institute of Standards reports that unplanned equipment downtime costs manufacturers an average of $50,000 per hour. Predictive maintenance systems help avoid these costs by identifying problems before failures occur.

Labor cost reductions come from automating routine tasks and optimizing workforce allocation. AI systems handle data entry, report generation, and monitoring tasks that previously required human attention. Workers can focus on higher-value activities requiring creativity and problem-solving skills.

Improved Decision Making

AI provides real-time insights by processing vast amounts of operational data instantly. Traditional reporting systems require hours or days to compile information. AI analytics deliver current status updates and trend analysis within minutes of data collection.

Pattern recognition capabilities help identify trends that humans might miss. Machine learning algorithms analyze thousands of variables simultaneously to detect correlations and predict outcomes. This analysis supports better strategic planning and operational adjustments.

Risk prediction improves through AI analysis of multiple data sources. Supply chain systems identify potential disruptions from weather, political events, or supplier issues. Manufacturing systems predict quality problems before they affect production output.

Enhanced Productivity and Scalability

Workflow optimization occurs through AI analysis of process efficiency and bottleneck identification. Systems recommend changes to improve throughput while maintaining quality standards. Resource allocation algorithms ensure optimal utilization of equipment and personnel.

Automated scheduling systems coordinate complex operations involving multiple constraints. Manufacturing facilities balance production requirements, equipment availability, and workforce schedules. Logistics operations optimize delivery routes and driver assignments for maximum efficiency.

Scalability improvements allow organizations to handle increased volume without proportional increases in staffing. AI systems process larger datasets and manage more complex operations as business growth occurs.

Implementation Strategy for AI Operations

Source: AI Development Services

Assessment and Planning Phase

Organizations begin by evaluating current operational capabilities and identifying high-impact use cases. The assessment examines data quality, system integration requirements, and workforce readiness for AI adoption.

Data preparation forms the foundation for successful AI implementation. Historical data requires cleaning, standardization, and organization before machine learning algorithms can process it effectively. Poor data quality undermines AI performance regardless of algorithm sophistication.

Use case prioritization considers potential business impact, implementation complexity, and organizational readiness. High-impact applications with clear success metrics typically receive priority for initial implementation.

Technology Selection Process

Platform selection requires matching AI capabilities to specific operational needs. Some organizations choose commercial solutions while others develop custom applications. The decision depends on available technical expertise, budget constraints, and integration requirements.

Key evaluation criteria include:

- Integration capabilities — Compatibility with existing operational systems

- Scalability features — Ability to handle growing data volumes and user bases

- Security standards — Protection for sensitive operational data

- Vendor support — Technical assistance and training resources

Proof-of-concept testing allows organizations to validate technology choices before full deployment. Limited pilot programs test AI solutions in controlled environments where failure won’t significantly impact operations.

Deployment and Change Management

Phased implementation reduces risk by deploying AI systems incrementally. Organizations might start with one department or location before expanding to other areas. This approach allows time to address issues and refine processes between phases.

Training programs address different skill levels across the organization. Technical staff learn system operation and maintenance procedures. End users receive training on new workflows and AI-enhanced processes. Management learns to interpret AI-generated reports and recommendations.

Performance monitoring establishes ongoing oversight of AI system effectiveness. Tracking both technical metrics like accuracy and business outcomes like cost savings helps ensure systems deliver expected value.

Common Challenges and Solutions

Data Quality and Integration Issues

Poor data quality represents the most common obstacle to successful AI implementation. Inconsistent formats, missing values, and inaccurate records prevent machine learning algorithms from learning effective patterns.

Data cleansing processes identify and correct quality issues before training AI models. Standardization efforts ensure consistent formats across different data sources. Integration projects connect previously isolated systems to provide comprehensive datasets for analysis.

Organizations establish data governance frameworks that maintain quality standards over time. Regular audits verify data accuracy and completeness. Automated validation rules catch errors before they affect AI system performance.

Workforce Adaptation Concerns

Employee concerns about AI replacing jobs require transparent communication and comprehensive training programs. Most AI implementations in operations augment human capabilities rather than eliminate positions entirely.

Retraining initiatives help workers develop skills for AI-enhanced roles. Quality control staff learn to interpret AI recommendations and handle exception cases. Maintenance technicians learn to use predictive analytics for more effective equipment care.

Change management programs address cultural resistance to AI adoption. Clear communication about role evolution and career development opportunities helps build acceptance and enthusiasm for new technologies.

Technical Implementation Complexity

System integration challenges occur when AI platforms must connect with existing operational technologies. Legacy systems may lack modern integration capabilities or use outdated data formats.

Professional implementation services help organizations navigate technical complexity. Experienced consultants assess integration requirements and develop custom solutions for connecting AI systems with existing infrastructure.

Gradual rollout strategies reduce technical risk by implementing AI capabilities incrementally. Organizations can test integrations thoroughly before expanding to additional systems or locations.

Measuring Success and ROI

Organizations implementing AI in operations typically see returns within six to 12 months according to research from Deloitte. Measurement approaches track both direct cost savings and indirect benefits like improved decision-making capabilities.

Direct ROI calculations include technology costs, implementation expenses, and ongoing operational costs. Benefits encompass labor savings, efficiency improvements, quality enhancements, and revenue increases from enhanced capabilities.

Key performance indicators vary by application but commonly include:

- Maintenance cost reductions — Typically 20 to 30 percent through predictive maintenance

- Forecasting accuracy improvements — Up to 50 percent error reduction in demand planning

- Process efficiency gains — Measured through throughput and cycle time improvements

- Quality improvements — Defect rate reductions and consistency enhancements

Continuous monitoring tracks AI system performance over time. Machine learning models require periodic retraining with new data to maintain accuracy. Performance reviews assess whether systems meet established targets and identify optimization opportunities.

Risk Management for AI Operations

AI governance frameworks address risks including data security, algorithmic bias, and regulatory compliance. The NIST AI framework provides structured guidance for identifying and managing AI-related risks.

Data security measures protect sensitive operational information through encryption, access controls, and audit trails. Regular security assessments identify vulnerabilities that could compromise system integrity or data protection.

Algorithmic bias can affect fairness in AI decision-making. Organizations test AI systems across different scenarios to identify potential bias issues. Bias mitigation techniques include diverse training data, algorithm adjustments, and human oversight of AI recommendations.

Regulatory compliance requirements vary by industry and geography. Healthcare organizations follow HIPAA guidelines for patient data protection. Financial institutions comply with regulations governing algorithmic decision-making in lending and risk assessment.

Frequently Asked Questions

How much does implementing AI for operations management cost?

Source: Virtasant

Implementation costs depend on project scope and organizational size. Pilot programs testing specific applications like predictive maintenance typically cost $50,000 to $200,000 including software, setup, and training.

Enterprise-wide deployments range from $500,000 to several million dollars depending on system complexity and integration requirements. Ongoing costs include software licensing, data storage, system maintenance, and model updates.

What types of data does AI need for operations management?

AI systems require historical operational data including equipment performance records, production metrics, quality measurements, and maintenance logs. Real-time data from sensors, monitoring systems, and transaction records improves prediction accuracy.

Data quality matters more than volume for successful AI implementation. Clean, consistent, and complete datasets enable better machine learning model performance than larger datasets with quality issues.

How long does AI implementation take in operations management?

Pilot programs typically require three to six months for planning, deployment, and initial testing. Full enterprise implementations take 12 to 24 months depending on system complexity and organizational scope.

Timeline factors include data preparation requirements, system integration complexity, training needs, and change management activities. Organizations with better data quality and technical readiness complete implementations faster.

Can small businesses benefit from AI in operations management?

Small businesses access AI through cloud-based platforms that eliminate large infrastructure investments. Subscription-based pricing models make AI technology accessible without significant upfront costs.

Cloud providers offer pre-built AI tools designed for smaller operations including inventory management, demand forecasting, and basic automation. These solutions require minimal technical expertise and can be implemented quickly.

Getting Started With AI Operations Management

Organizations ready to implement AI in operations management begin with assessment of current capabilities and identification of high-impact use cases. The most successful implementations start with specific problems that have clear success metrics rather than attempting broad transformations.

Data preparation often requires more time and effort than anticipated. Organizations benefit from cleaning and organizing historical data before selecting AI technologies. Quality data forms the foundation for effective machine learning models.

Professional guidance can accelerate implementation while avoiding common pitfalls. AI consulting services help assess readiness, select appropriate technologies, and develop realistic implementation timelines based on organizational capabilities and constraints.

AI for operations management transforms traditional approaches through machine learning, predictive analytics, and automation technologies. Success requires careful planning, quality data, and attention to organizational change management along with realistic expectations about implementation timelines and outcomes.