Application-Specific Integrated Circuits (ASICs) and Field-Programmable Gate Arrays (FPGAs) represent two fundamentally different approaches to implementing digital logic in semiconductor devices.

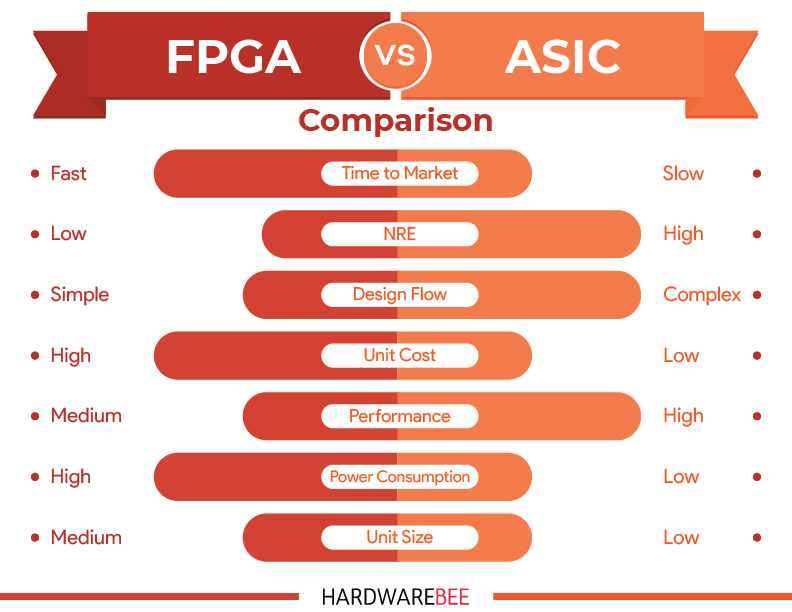

The choice between ASICs and FPGAs affects performance, power consumption, development time, and cost in ways that shape entire product strategies. ASICs deliver custom-designed circuits optimized for specific functions, while FPGAs provide reconfigurable hardware that can be programmed after manufacturing.

Understanding the technical and economic tradeoffs between ASICs and FPGAs helps engineers select the right technology for their applications. Each approach offers distinct advantages depending on production volume, performance requirements, and development constraints.

Modern electronics rely heavily on both technologies, from smartphones using custom ASICs to data centers deploying FPGAs for AI acceleration. The decision between ASICs and FPGAs often determines project success in competitive markets.

Source: Utmel

What Are ASICs and FPGAs

ASICs and FPGAs represent two distinct approaches to creating specialized computer chips for specific tasks. Both technologies solve the problem of performing calculations faster and more efficiently than general-purpose processors, but they accomplish this goal through fundamentally different design philosophies.

ASICs deliver maximum performance and efficiency by creating custom hardware optimized for one specific function. FPGAs provide flexibility and adaptability by allowing engineers to reconfigure the hardware for different tasks after manufacturing.

Application Specific Integrated Circuits Explained

Application Specific Integrated Circuits are custom-designed semiconductor chips built to perform one specific function or set of related functions. Engineers design every component of an ASIC from scratch to optimize performance for a particular application.

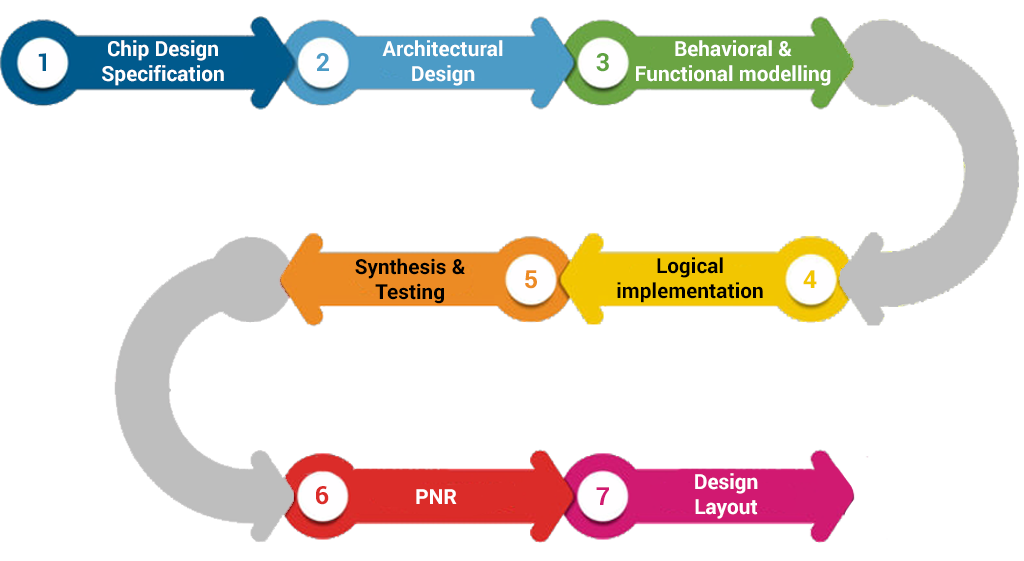

The manufacturing process begins with detailed specification and design phases where engineers define the exact functionality required. Physical design and layout represent the most complex phase, where engineers arrange transistors, wires, and interconnects on the silicon wafer.

Source: eInfochips

Key characteristics of ASICs include:

- Fixed functionality — Cannot be modified after manufacturing

- Custom optimization — Every transistor designed for the specific application

- High performance — Optimized signal paths enable maximum speed

- Low power consumption — Eliminates unnecessary circuitry

- High development cost — Requires expensive mask sets and lengthy design cycles

Field Programmable Gate Arrays Explained

Field Programmable Gate Arrays are reconfigurable semiconductor devices that engineers can program and reprogram to implement different digital circuits. FPGAs contain arrays of programmable logic blocks connected through configurable routing networks.

The core building blocks consist of configurable logic blocks containing lookup tables, flip-flops, and multiplexers. These blocks can implement various logic functions depending on how engineers program them. Engineers describe the desired functionality using hardware description languages like VHDL or Verilog.

Source: ResearchGate

Key characteristics of FPGAs include:

- Reconfigurable design — Can be reprogrammed for different functions

- Parallel processing — Multiple operations execute simultaneously

- Rapid prototyping — Quick implementation and testing cycles

- Field updates — Functionality can be modified after deployment

- Higher power consumption — Programmable overhead increases energy usage

ASIC vs FPGA Performance Comparison

When engineers design digital systems, they face a fundamental choice between two technologies that handle computing tasks differently. ASICs deliver specialized performance for specific applications, while FPGAs provide flexible processing capabilities that can adapt to changing requirements.

Processing Speed and Throughput Analysis

ASICs typically achieve higher clock frequencies than FPGAs implementing identical functions. The custom-designed signal paths in ASICs minimize delays and optimize timing, allowing operations at three to four times higher frequencies compared to FPGA implementations.

Source: AnySilicon

The speed advantage comes from optimized signal paths where ASICs eliminate routing overhead through direct connections. Custom logic gates mean transistors are arranged specifically for the target application, while reduced propagation delays occur because shorter wire lengths decrease signal travel time.

FPGAs compensate for lower clock speeds through parallel processing capabilities. The programmable architecture allows multiple operations to execute simultaneously across different logic blocks, enabling FPGAs to achieve high throughput despite operating at lower frequencies.

Power Consumption and Energy Efficiency

Power consumption stands as one of the most critical differentiating factors between ASICs and FPGAs. ASICs consume significantly less power than FPGAs due to their custom-optimized architecture, typically requiring five to ten times less dynamic power than equivalent FPGA implementations.

Source: ResearchGate

FPGAs consume substantial static power due to their programmable architecture. Configuration memory cells, programmable switches, and routing infrastructure contribute to leakage current even when unused in a particular design.

The power efficiency gap affects system-level design decisions. ASICs deliver higher performance while consuming less power, making them suitable for battery-powered devices and applications with strict thermal constraints.

Development Process and Time to Market

The development workflows for ASICs and FPGAs follow different paths that directly impact project timelines and resource requirements. ASIC development requires a sequential process where each phase completes before the next begins, while FPGA development allows for more parallel activities and iterative refinement.

Design Flow Complexity and Tool Requirements

ASIC development involves a complex, multi-stage process that requires specialized tools and expertise at each phase. The workflow begins with detailed specifications and progresses through multiple verification stages before reaching physical implementation.

ASIC design tools require expensive licensing fees and specialized training. A complete ASIC toolchain can cost hundreds of thousands of dollars annually for a design team. FPGA development tools are generally more accessible and cost-effective, with vendors typically providing integrated development environments.

Time to Market Implications

ASIC development timelines typically range from 12 to 24 months from initial design to production-ready silicon. Any design changes discovered after tape-out extend timelines by several additional months.

FPGA-based products can reach market within three to six months of design completion. The ability to purchase FPGAs off-the-shelf eliminates manufacturing lead times and enables rapid product deployment.

Cost Structure and Economic Considerations

The economic analysis between ASICs and FPGAs represents a major decision factor for technology selection, encompassing multiple cost components that affect project viability and long-term profitability.

Source: ResearchGate

Non Recurring Engineering and Development Costs

ASIC non-recurring engineering costs are substantial due to custom design requirements and fabrication preparation. The mask set creation alone represents one of the largest cost components, ranging from $150,000 for older technology nodes to several million dollars for advanced processes.

FPGA non-recurring engineering costs are significantly lower because these devices use existing silicon and require no custom fabrication. The primary expenses involve purchasing development tools and engineering time for design implementation.

Per Unit Production Costs and Volume Economics

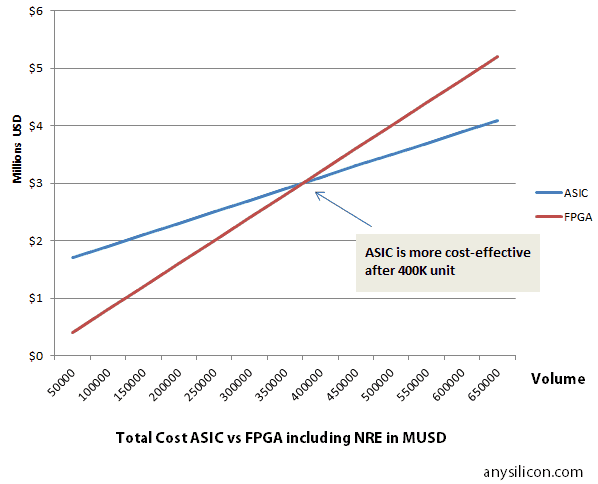

Manufacturing costs per device determine ongoing expenses and represent the primary economic factor for high-volume products. FPGAs typically cost more per unit than ASICs due to their programmable architecture overhead and lower manufacturing volumes.

The crossover point where ASICs become more economical than FPGAs typically occurs between 5,000 and 50,000 units, though this varies based on design complexity and device specifications.

Application Domains and Use Case Analysis

The selection between ASICs and FPGAs varies significantly across application domains based on performance requirements, power constraints, flexibility needs, and cost considerations.

Source: ResearchGate

High Performance Computing and Data Centers

Data centers require massive computational power to handle everything from web searches to scientific simulations. Microsoft’s Project Catapult demonstrates large-scale FPGA deployment across datacenter infrastructure, where FPGAs accelerate web-scale services and distributed applications.

ASICs dominate applications with well-defined, high-volume workloads. Google’s TPU exemplifies the ASIC approach, with chips dedicated entirely to matrix multiplication operations common in machine learning.

AI and Machine Learning Acceleration

Artificial intelligence workloads present unique computational challenges that have driven specialized hardware development. Neural network inference represents a mature application where ASICs demonstrate clear advantages through transistors optimized for AI workloads.

Edge AI deployment presents different constraints including power limitations, size restrictions, and variable workloads. FPGAs offer advantages for edge applications requiring adaptability to different AI models or algorithms, as discussed in our AI consulting services.

Automotive and Aerospace Systems

Safety-critical applications in automotive and aerospace systems impose stringent requirements for reliability, real-time performance, and environmental durability. FPGAs excel in applications like flight control systems where consistent response times are essential.

Real-time control systems in automotive applications include engine management, transmission control, and advanced driver assistance systems. These applications require precise timing control and rapid response to sensor inputs.

When to Choose ASIC vs FPGA

The decision between ASICs and FPGAs depends on balancing performance, cost, development time, and flexibility requirements. Each technology serves different scenarios based on production volumes, performance needs, and risk tolerance.

Source: ResearchGate

Volume Thresholds and Break Even Points

Production volume determines which technology provides better economics. The crossover point typically occurs between 5,000 and 50,000 units, though this varies based on design complexity and specifications.

Companies with uncertain demand benefit from FPGA flexibility. FPGA devices can serve multiple products through reconfiguration, reducing inventory risk compared to fixed-function ASICs.

Performance vs Flexibility Requirements

Performance and adaptability represent competing priorities that guide technology selection. ASICs excel in raw performance while FPGAs provide programming flexibility.

ASIC selection criteria include maximum performance requirements where three to four times higher clock speeds are possible, lowest power consumption needs where five to ten times more efficiency is available, and stable, well-defined specifications.

FPGA selection criteria include rapid prototyping requirements, evolving specifications or standards, multiple functionality needs in one device, and real-time reconfiguration capabilities.

Frequently Asked Questions

What production volume justifies switching from FPGA to ASIC?

The economic break-even point typically ranges from 5,000 to 50,000 units, depending on design complexity and cost targets. Simple designs might justify ASIC development at lower volumes, while complex implementations may require 100,000 or more units to offset development costs.

A practical example demonstrates the economics: a system requiring one million units annually with a target unit price of $2.50 could justify a $3 million ASIC development cost, achieving return on investment within two years through per-unit savings.

How much faster are ASICs compared to FPGAs for the same function?

ASICs typically operate at three to four times higher clock frequencies than equivalent FPGA implementations. The custom-designed signal paths in ASICs minimize delays and optimize timing, while FPGAs include programmable routing overhead that introduces additional delays.

However, FPGAs can compensate for lower clock speeds through parallel processing capabilities, sometimes achieving comparable overall throughput through simultaneous operations across multiple logic blocks.

Can you migrate from FPGA prototypes to ASIC production?

FPGA prototyping often serves as a pathway to ASIC implementation for high-volume products. The register transfer level codebase can ideally be identical for both FPGAs and ASICs, enabling companies to build prototypes with FPGAs before switching to ASICs for volume production.

This approach provides critical validation capabilities that simulation alone cannot provide, including real-time software execution, hardware-software integration testing, and system-level validation before committing to expensive ASIC fabrication.

What power consumption differences exist between ASICs and FPGAs?

ASICs consume five to ten times less power than equivalent FPGA implementations due to their custom-optimized architecture. The programmable infrastructure in FPGAs introduces overhead that increases both static leakage current and dynamic switching power.

This power efficiency difference affects battery life in portable devices, operational costs in large deployments, and thermal management requirements across all applications.

Which technology offers better long-term availability and support?

FPGA manufacturers typically maintain device families for extended periods and provide migration paths to newer technologies. Long-term support includes ongoing vendor support and regular updates to development tools.

ASIC long-term support depends on foundry availability and continued demand for specific process technologies. The fixed nature of ASICs means no software updates are required, but hardware obsolescence requires complete redesign when process nodes become unavailable.