Artificial intelligence in manufacturing refers to computer systems that can learn, analyze data, and make decisions to improve production processes, quality control, and equipment maintenance.

Manufacturing companies are rapidly adopting AI technologies to solve longstanding challenges like equipment breakdowns, quality defects, and supply chain disruptions. According to IBM's analysis of AI in manufacturing, 93 percent of manufacturing industry leaders report they are already using some form of AI in their operations. The technology processes vast amounts of data from sensors and machines to optimize efficiency and reduce downtime through real-time pattern recognition.

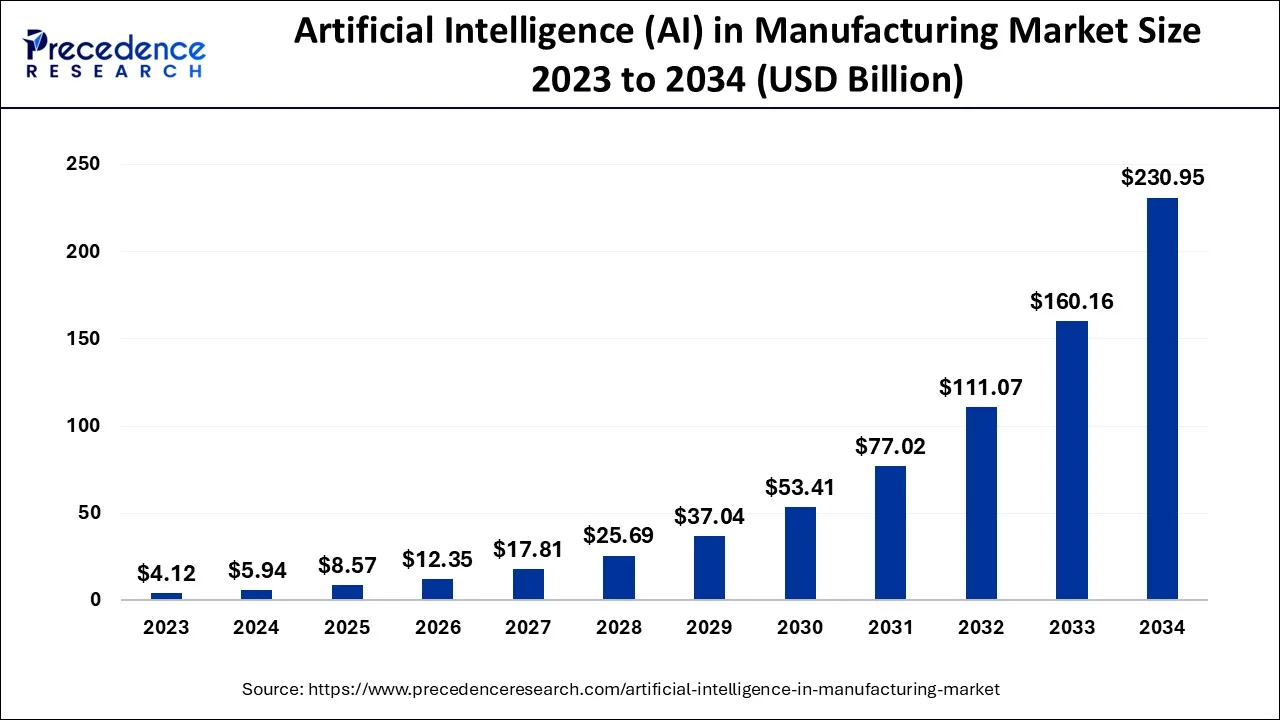

Source: Precedence Research

The National Institute of Standards and Technology has announced funding of up to $70 million over five years for a new Manufacturing USA institute focused specifically on using artificial intelligence to increase the resilience of U.S. manufacturers. This investment reflects the critical importance of AI technologies for maintaining manufacturing competitiveness in a complex global marketplace.

What AI Technologies Are Used in Manufacturing

Source: ResearchGate

Machine learning algorithms form the foundation of most AI applications in manufacturing environments. These systems analyze historical data from sensors, equipment logs, and production records to identify patterns that indicate potential problems or optimization opportunities. Unlike traditional rule-based systems, machine learning models continuously improve their performance as they process more operational data. These capabilities align closely with AI agent perception principles, where systems understand and interpret their manufacturing environment through data analysis.

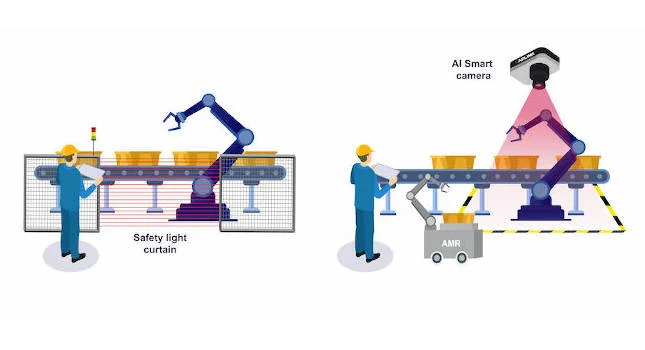

Computer vision technology uses AI-powered cameras and image processing to inspect products and monitor safety conditions throughout production facilities. These systems can detect surface defects, verify assembly accuracy, and ensure packaging quality with greater speed and consistency than human inspectors. Computer vision systems can improve defect detection accuracy by up to 95 percent in critical applications such as medical equipment manufacturing.

Source: Labellerr

Digital twin technology creates virtual replicas of physical manufacturing processes that update continuously with real-time data from Internet of Things sensors. These virtual models enable manufacturers to test changes and optimize operations without disrupting actual production lines. Digital twins support scenario modeling and analysis that helps manufacturers predict the impact of process modifications before implementation.

Source: Toobler

Natural language processing enables workers to interact with manufacturing systems using voice commands and conversational interfaces. These AI systems can summarize technical documentation, generate troubleshooting procedures, and provide real-time guidance to technicians during maintenance operations.

How AI Improves Manufacturing Efficiency

Source: BizTimes

AI-driven automation accelerates production by handling repetitive tasks and optimizing workflows with minimal manual intervention. Integrated AI systems create streamlined processes from raw materials to finished products that reduce cycle times and increase throughput. Manufacturing organizations report significant productivity improvements through AI systems that can simultaneously monitor and optimize multiple process variables. Understanding the difference between generative AI and predictive AI helps manufacturers choose the right AI approach for their specific operational needs.

Predictive analytics powered by machine learning helps manufacturers optimize resource allocation and reduce waste generation. AI systems predict optimal production sequences, minimize changeover times between different products, and optimize material usage to improve yield rates. These improvements in resource efficiency translate directly to cost savings and environmental benefits.

Real-world implementations demonstrate substantial productivity gains from AI adoption:

- Answer-finding time — Reduced from 6 minutes to 10 seconds, representing a 3,500 percent improvement in information access efficiency

- Training time for technicians — Decreased from 18 months to under 6 months through AI-powered learning systems

- Energy optimization — AI systems analyze consumption patterns and optimize production schedules to take advantage of lower energy costs during off-peak periods

Source: Nielsen Norman Group

Key Manufacturing AI Applications

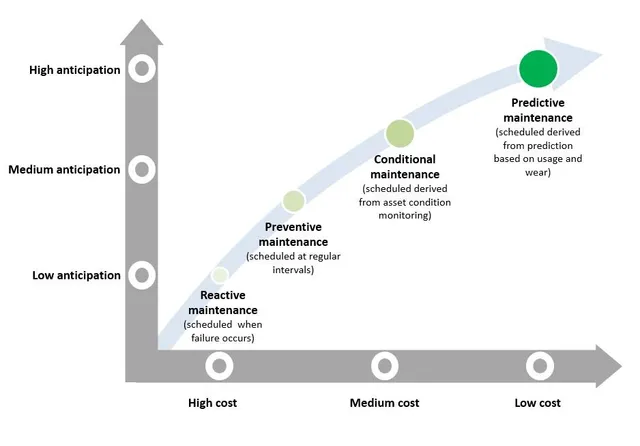

Predictive maintenance has emerged as one of the most successful AI applications in manufacturing operations. Machine learning algorithms analyze sensor data from machinery to forecast failures before they occur, enabling manufacturers to schedule maintenance during planned downtime periods. Research indicates predictive maintenance can reduce equipment downtime by up to 50 percent and lower maintenance costs by 10 to 40 percent.

Source: OCP-MS

AI-powered quality control systems utilize computer vision and machine learning to identify defects and quality variations in real-time. These systems inspect products continuously without fatigue, providing consistent evaluation criteria that eliminate variability associated with human inspection. BMW Group's plant in Regensburg estimates that AI-supported predictive maintenance systems save more than 500 minutes of disruption per year at a single facility.

Source: NVIDIA

Supply chain optimization through AI addresses demand forecasting, inventory management, and risk mitigation challenges. Machine learning algorithms predict customer demand by analyzing historical data, market conditions, and real-time consumer behavior patterns. AI systems can identify potential supply chain disruptions by analyzing weather patterns, geopolitical events, and supplier performance metrics.

Production planning and scheduling systems use AI to optimize manufacturing operations based on real-time conditions and changing requirements. These systems analyze equipment capacity, material availability, workforce schedules, and energy costs to generate optimal production schedules.

Benefits and ROI of Manufacturing AI

Source: Virtasant

Cost reduction represents a primary financial benefit of AI implementation across multiple operational categories. Automation, predictive analytics, and improved quality control contribute to significant savings through reduced labor expenses, lower maintenance costs, and optimized energy consumption. McKinsey research indicates that predictive maintenance alone represents potential value impact of $0.5 trillion to $0.7 trillion across global businesses.

Quality improvements from AI implementation enable consistent, objective inspection processes that exceed human capabilities in accuracy and reliability. AI-driven quality systems can reduce defect rates to near-zero levels, preventing costly rework, warranty claims, and product recalls. Early detection and correction of quality issues reduces waste and prevents defective products from progressing through expensive production stages.

Safety enhancements through AI monitoring and predictive analytics protect workers and equipment from potential hazards. AI systems can analyze historical accident data and environmental conditions to identify patterns that indicate increased safety risks. Collaborative robots equipped with AI can handle dangerous tasks while monitoring work environments for unsafe conditions.

Manufacturing AI investments are projected to reach $16.7 billion by 2026 according to World Economic Forum data. Organizations implementing AI solutions report returns through improved asset utilization, reduced unplanned downtime, and enhanced operational efficiency.

Source: Grand View Research

Common AI Implementation Challenges

Source: ResearchGate

Data quality issues represent one of the most significant barriers to successful AI deployment in manufacturing environments. Many manufacturing facilities collect data from legacy systems that weren't designed for AI applications, resulting in incomplete, inconsistent, or poorly formatted information. Without clean, standardized data, AI systems can't learn effectively or make accurate predictions. AI infrastructure planning becomes crucial for addressing these data quality challenges from the foundation up.

Integration complexity with existing manufacturing execution systems creates technical hurdles that can delay or derail AI projects. Many manufacturers operate with a mix of older equipment and newer digital systems that don't communicate well with each other. Connecting AI platforms to these diverse systems often requires custom software development and careful coordination with ongoing production schedules.

Workforce concerns about job displacement can create resistance to AI adoption among employees who fear technology will replace their roles. Manufacturers report better success when they involve workers in AI planning and clearly communicate how the technology will augment rather than replace human capabilities.

Cybersecurity risks increase as manufacturers connect more equipment to networks and cloud-based AI systems. The integration of AI with operational technology creates new attack surfaces that require specialized security measures beyond traditional IT protection strategies.

Future Trends in Manufacturing AI

Edge computing capabilities are enabling AI processing directly at production sites, reducing latency and improving real-time decision-making for critical manufacturing processes. This distributed approach to AI deployment will enable more responsive and autonomous manufacturing systems that can adapt instantly to changing conditions.

Source: FSP Group

Advanced robotics integration with AI is creating more flexible and capable automation systems that can handle complex tasks requiring dexterity, adaptability, and decision-making capabilities previously limited to human workers. These intelligent robotic systems will enable mass customization and rapid reconfiguration of production lines to meet changing market demands.

Generative AI applications are beginning to revolutionize product design and development processes by automatically creating design variations, optimizing material usage, and generating manufacturing instructions. This technology will enable faster time-to-market for new products while reducing design and development costs. Understanding agentic AI vs generative AI differences helps manufacturers select the most appropriate AI approach for their specific needs.

The convergence of AI with other emerging technologies such as 5G networks, quantum computing, and advanced materials science will create new possibilities for manufacturing innovation. These technological combinations will enable unprecedented levels of automation, optimization, and customization across manufacturing operations.

How to Implement AI in Manufacturing

Source: MDPI

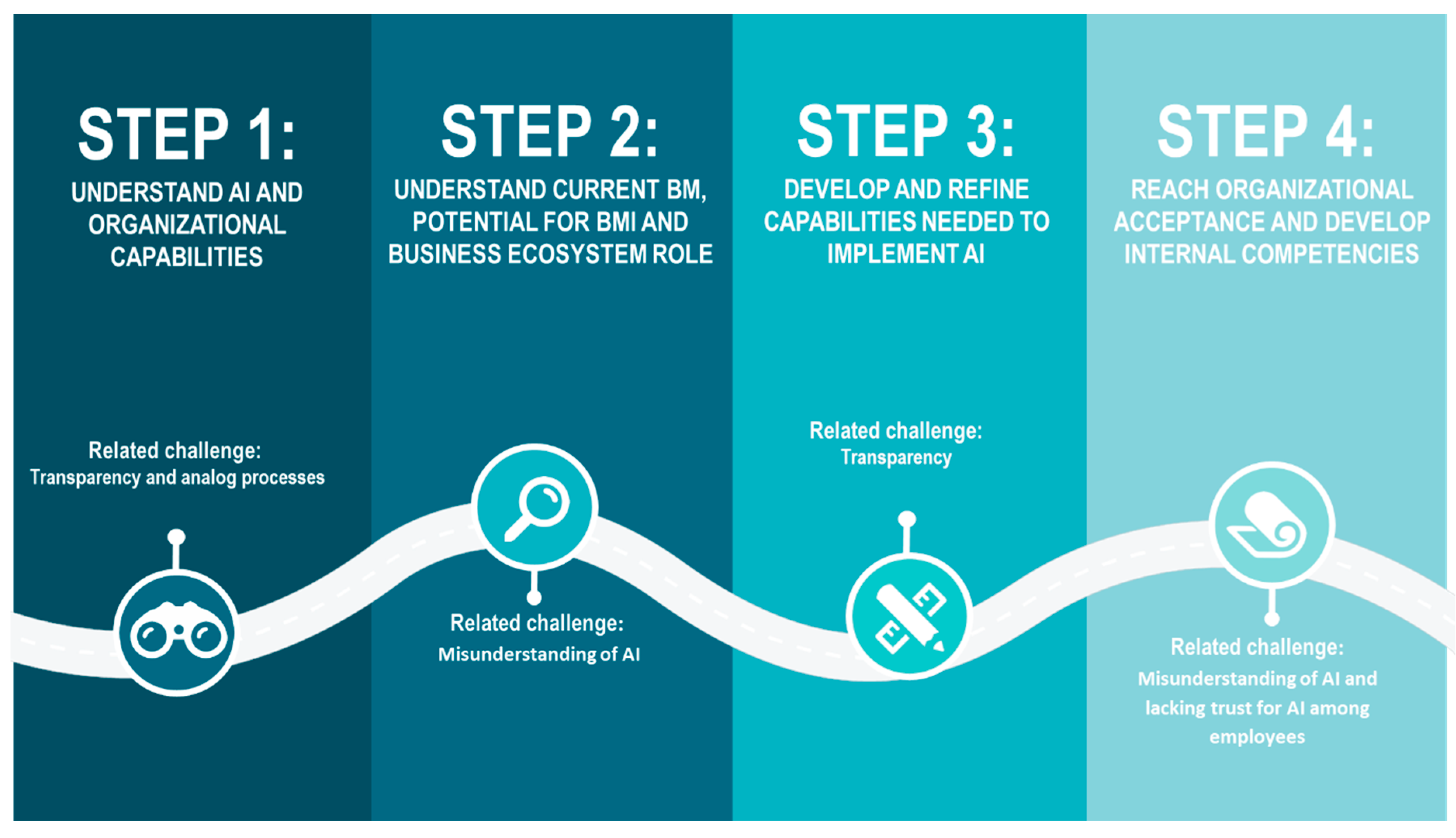

Successful AI implementation requires a strategic approach that begins with careful assessment of organizational readiness and clear definition of business objectives. Manufacturers can start by identifying high-impact use cases that offer significant return on investment potential while building internal capabilities and confidence with AI technologies. Professional AI consulting services can help organizations navigate this complex implementation process and avoid common pitfalls.

Pilot projects provide valuable learning opportunities and demonstrate AI value before committing to large-scale implementations. These initial deployments work best when they focus on well-defined problems with measurable outcomes, such as reducing specific equipment downtime or improving particular quality metrics.

Infrastructure preparation addresses data collection, storage, and processing requirements that enable AI systems to function effectively:

- Network capabilities — Upgrading bandwidth and connectivity to support real-time data transmission

- Sensor installation — Adding IoT devices to collect relevant operational data

- Cybersecurity measures — Establishing protection against AI-specific threats and vulnerabilities

- Data management — Creating systems for cleaning, storing, and accessing manufacturing data

Source: Cyber Security News

Workforce development and change management represent critical success factors that require sustained attention throughout the implementation process. Organizations benefit from investing in training programs that prepare workers for collaboration with AI systems while addressing concerns about job impacts and technological change. This approach ensures responsible AI implementation that considers both technological and human factors.

AI technologies have fundamentally transformed manufacturing operations by enabling predictive maintenance, automated quality control, and intelligent production optimization that deliver measurable improvements in efficiency, cost reduction, and product quality. The widespread adoption of AI across manufacturing organizations demonstrates the technology's proven ability to address critical operational challenges while generating substantial return on investment.